RAPID PROTOTYPE

Rapid Prototype

With latest CNC and Rapid Prototyping technologies, various workshops held from time to time to provide our highly skilled technicians with exceptional capabilities for rapid prototype development. We carry out Prototyping during various phases of each project. Thus maximum possible efficient development is ensured. Rapid Prototyping involves getting mock-ups of the product. This is then reviewed evaluated and refined until the best quality product is achieved.

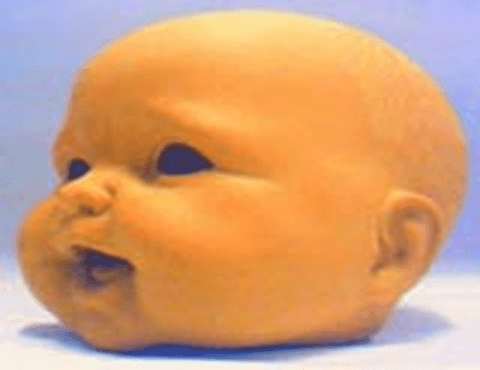

Prototyping gives the opportunity to get a clear idea of aesthetics, beside allowing one to touch, feel, and get a sense of its strength and size. Prototypes are essential to understand the ergonomic aspects of the product.

Visual Appearance Models

Allow our team to understand the design intent, use techniques of simulation & prototyping in terms of Colour Material Finish.

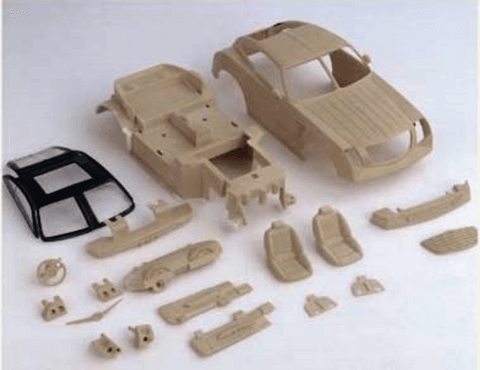

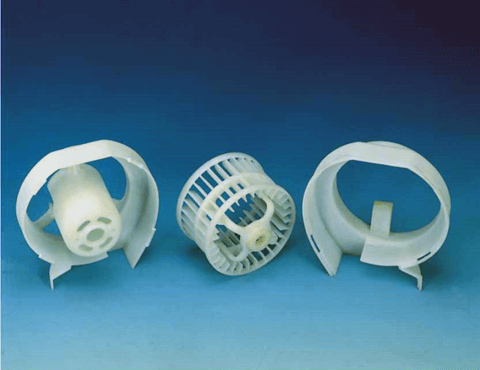

Functional Prototypes

Using advanced Rapid prototyping techniques like (SLA), (SLS), (CNC machining) to create accurate prototypes be it for aesthetic evaluation, fit and function testing or simply for design verification. We also create early evaluation mock-ups using Foam, POP, and Styro-foam and Ciba wood.

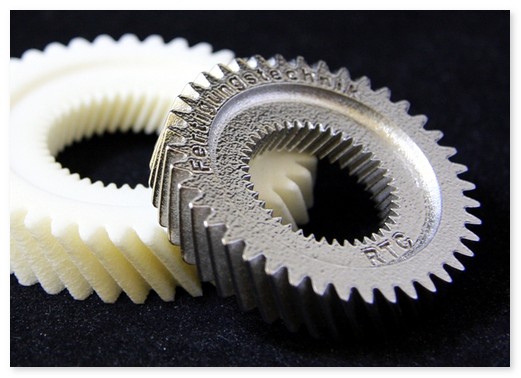

CNC Machined Prototypes

This precision machining enables form fitting and functional testing in the early stage of product development with a wide selection of engineering thermoplastics and digital materials simulating different mechanical properties of final products.

Silicone Mold & Vacuum Casted Parts

If you need a small quantity of plastic pieces with the quality of injection moulded components, Vacuum Casting at Materialise might be exactly what you are looking for.