Blog

PCB and PCBA, are they the same or different?

You and a lot of other people might not truly understand the difference between PCB and PCBA and may use these terms interchangeably but they are actually two distinct terms.

The main difference between these two terms is that PCB refers to a blank circuitry board, while PCBA refers to a board that contains all of the necessary electronic components for the board to function as needed. A PCB is not yet functional because it does not have the required components in place, while a PCBA is a complete and functional board. PCB and PCBA are two different parts of the same process — a PCBA is built on top of an existing PCB.

I’ll give the definitions before highlighting the salient characteristics and roles of each and after I will give the differences.

What are PCBs?

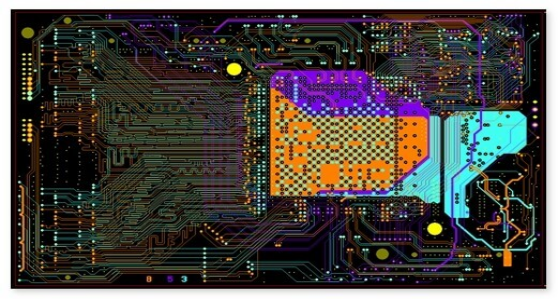

I will start by explaining what PCBs are. Also known as Printed circuit board, they are the foundation of modern electronic devices and they mechanically support and electronically connect electronic components. The boards can be made by laminate materials like fiber glass or composite epoxy and they contain conductive pathways that connect different parts of the board. According to the predetermined PCB design, these pathways are either printed or engraved into the board.

There are 3 main types of PCBs

Single-Layered: coated with a single layer of conductive material and one layer of solder mask

Double-layered: have a layer of conductive material on the top and bottom of board.

Multi-layered: have more than 2 conductive layers.

Others types include Flexible PCB, rigid PCB, and flex-rigid PCBs

PCBs are mainly used in

●Computers

●Mobile phones

●Lighting systems

●Medical imaging systems

●Pacemakers

●Engine management systems

●Industrial controls

●Telecom towers

●Data storage equipment

●Satellite systems. And so much more

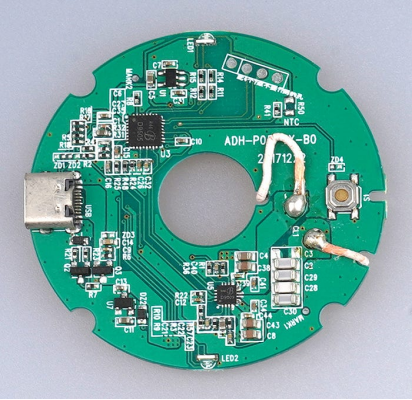

What is PCBA?

Also known as Printed Circuit Board Assembly. This can be defined as a completed PCB assembly that contains all of the electronic components needed to make the board function as required.

For PCB assembly, a company may employ one of two major techniques:

1. Surface-Mount Technology (SMT)

This assembly procedure involves attaching electronic components to a PCB's surface. Higher connection density is possible thanks to its high levels of automation and flexibility. It allows manufacturers to incorporate intricate circuitry into tiny components.

There are 4 steps for SMT

Step 1: Preparing the PCB

Step 2: Placing the components

Step 3: Reflow soldering

Step 4: Inspection

2. Thru-Hole Technology

During this assembly procedure, holes are drilled into a PCB so that leads, which are electronic components, can be joined. Though it is an older technique than SMT, it strengthens the bond between the board and the components, leading to more dependable and long-lasting assemblies.

Thru-hole assembly can be either fully automated or semi-automated. The steps of the PCBA thru-hole process include:

Step 1: Drilling the holes

Step 2: Placing the leads

Step 3: Soldering

Step 4: Inspection

The Differences;

We now know the definitions we can talk about the differences. The two distinct phases of the same general process provide PCB and PCBA. A PCB is an empty circuit board without any attached electronic components, whereas a PCBA is a finished assembly with all the parts needed for the board to operate as intended for the application. A PCBA is ready for usage in an electronic device while a PCB is not yet functional.

Due to the numerous components and procedures required in PCB assembly, manufacturing a finished PCBA is a more complex process than producing a blank board. Without a PCB, it also costs more to construct a PCBA. The first step in the process is PCB manufacturing, and PCBA manufacturing is builds on that.

Our product and electronic design Services.

At Topwell Spring Development Limited we provide services including product design, PCB and PCBA design, mechanical and electrical engineering, prototype testing and so much more according to the customer’s design needs.

Bring your products into the world. Work with us to design and engineer your latest innovation.

For inquiries Contact:

Leo- Overseas sales

leo@topwellspring.com

WhatsApp: +8618025199908