Blog

What is Injection Molding and why you should choose Topwell Spring Development Ltd.

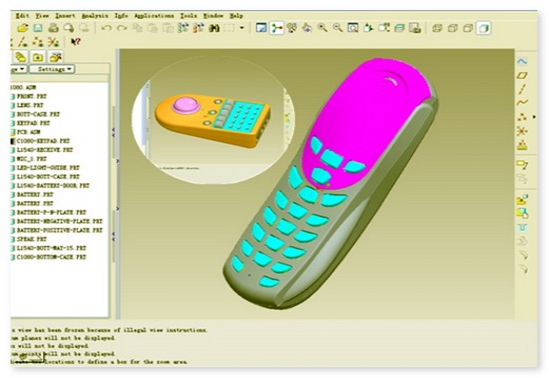

Injection molding is a manufacturing process for producing parts by injecting molten material into mold. A range of materials, including metals, glassware, elastomers, confections, and most frequently thermoplastic and thermosetting polymers, can be used for this.

How it’s done.

We start by making the mold itself. Most molds are composed of metal, typically steel or aluminum. Afterward, they are precisely machined to generate a product that matches the product’s description.

The mold-maker creates the mold, and then using a helical-shaped screw, the part’s material is mixed after being put into a heated barrel. Heating bands bring the melted material into the barrel, which is then injected into the cavity of the mold where it cools and solidifies to take on the shape of the mold. When the material has been set, the moveable platen that holds the molding tools opens, allowing the item to be removed using ejector pins.

A two-shot mold, double injection, or 2K mold, is an injection molding technique that allows different materials to be blended into one object. This method may be used to give plastic products a plush or rubber feel, add color to a part, or create products with various performance qualities.

Molds might have a single cavity or several cavities. Multiple cavity molds can produce pieces with the same geometry or with distinct geometries in each cavity.

Since aluminum has poor mechanical qualities and is vulnerable to wear, distortion, and damage from the injection and clamping pressures, it is not recommended for high-volume manufacturing or components with tight dimensional tolerances. Steel molds are more costly than aluminum molds while being more robust and precise.

The form and features of the component, the materials used for the part and the mold, and the characteristics of the molding machine all need to be carefully designed for the injection molding process. As a result, while using injection molding, a number of factors need to be taken into account.

l Financial

l Production Quantity

l Production Considerations

l Design Factors

There are ways you can reduce mold costs.

l Remove unnecessary features.

l Use a core cavity approach.

l Reduce cosmetic finishes.

l Design parts that self-mate.

l Modify and re-use existing molds.

l Monitor DFM analysis.

l Use a multi-cavity or family type of mold.

l Consider your part sizes.

Advantages of Injection molding.

l Injection molding produces minimal wastage.

l Allows for flexibility. Nearly any plastic part can be produced using this manufacturing process.

l The injection molding process provides fast production at high output.

l Due to the process being mainly machine orientated, the cost of labor is lower than in other manufacturing processes.

l As the parts produced are identical, good consistency is guaranteed.

l Compatible with a wide range of materials and colors.

l Materials can be reused.

Why Choose Topwell Spring Development Ltd.

Topwell Spring Development Limited (TOPWELL) has more than 27 years of expertise and experience in manufacturing Injection Molds. Over the years we have manufactured Molds of distinguishable sizes and intricacy to the satisfaction of our customers.

Today Topwell has carved a niche for itself in the field of Precision plastic Injection Mould and molded components, evolving to be one of the leading custom Injection molders in the field of the engineering industry. Due to our ability to maintain extreme fine tolerances coupled with extensive Plastic Injection molding expertise, the development of tooling and manufacturing components has turned out to be one of our various strength points.

We provide end-to-end tooling solutions for a diverse range of industries. We pride ourselves in offering our clients high-quality products, from our facilities, with our built-in-house tooling room equipped with advanced machines, utilizing the newest technologies.

We also provide

l Electronic design services.

l Multi-Layer PCB Design

l Architecture Design

l Schematics Design

l PI/SI Analysis and

l Thermal Analysis.

For inquiries Contact:

leo@topwellspring.com

WhatsApp: +8618025199908